Kuro

The Ultimate Tensile Strength

Giving you the latest best protection with the state of the art Graphene Nanotubes infused coating. Safeguarding car clear coat/lacquer from contaminants.

PRODUCT DESCRIPTION

Unique Selling Point

Electrostatic Dissipative

With the inclusion of ESD raw material, Kuro has achieved the result of extremely low dust collection. ESD has the same benefits as Anti-Static except its resistance is much lower and tends to deliver greater long-term results. As such, Kuro coated car stays cleaner than ceramic or glass coating coated car.

Infusion of Graphene Nanotubes

Kuro is infused with ultrasonically dispersed Graphene Nanotubes, but not Graphene Oxide or Reduced Graphene Oxide. Graphene Nanotubes are Graphene structurally modified into sheet and tube form at the molecular level; our formula exhibits different characteristics from normal Graphene Ceramic Coating.

10H Hardness

The further upgrade of material hardness has increased the hardness from 9h to 10h. Graphene Nanotubes is known as 100 times stronger than steel and it is regarded as one of the strongest materials known to human.

Corrosion-resistant Barrier

The main ingredient Kuro possesses decent chemical inert properties and does not react to most of the chemicals. With the add-on of Graphene Nanotubes, the formula is now obtained remarkable chemical inert properties and showing high resistance towards bird dropping and tree sap; in TEVO, it is called a Corrosion-resistant Barrier and an upgrade form of chemical resistance.

Long Durability

The durability of the coating is often affected by environmental factors and human factors, such as acidic rainwater, ultraviolet, polluted contaminant, tar, and alkaline car shampoo. The in-house chemist team managed to prolong the lifespan of the coated surface to 5 years with minimal maintenance by greatly improving the stability of chemical position and chemical resistance.

Enhanced Hydrophobicity & Sliding Angle

The proprietary formula from TEVO has managed to increase the water contact angle from 110 degrees to almost 120 degrees and lowered down the sliding angle by 5 to 10 degrees. The combination of these accomplishments has led to better easy cleaning properties and watermark resistance ( after full cure ). Water slides off easily in comparison with normal Ceramic Coating upon contact with Kuro coated surface.

Shiro

Dynamic Duo to your PPF

Special formulated product specifically to reduce watermark on Paint Protection Film (PPF), vinyl decal, car wrap, and aftermarket matte paint.

One of the kind in it's category.

PRODUCT DESCRIPTION

Unique Selling Point

One For All

An extremely versatile formula that can be applied on multiple materials such as Paint Protection Film, Vinyl Decal, car wrap, and matte paint. The unique oil-based formula forms a thicker layer of coating on top of the surface than standard car coating in the industry. The application of new Shiro is fairly easy despite high viscosity and thicker layer; the steps are exactly the same as applying standard car coating except for the duration before buffing.

Flexibility

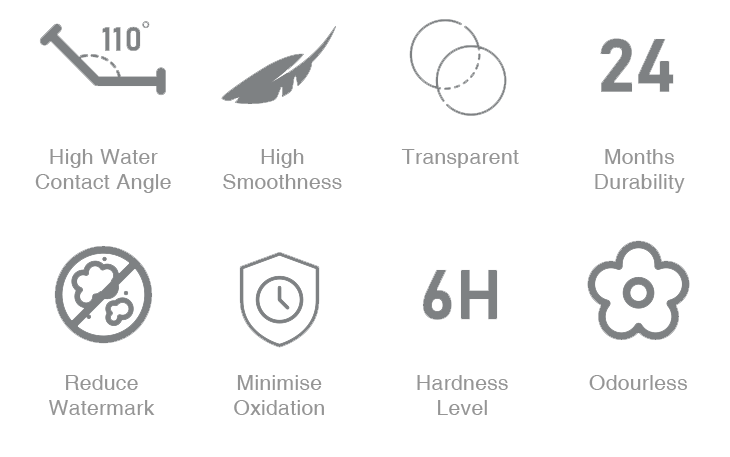

Shiro has the total opposite characteristic from Kuro; the formula is scaled at 6H of pencil hardness and it is invented in such a direction to have better flexibility properties. Numerous advantages are spotted in a softer coating such as better impact absorption to prevent the coating cracks, easier to alter, to avoid overpolish the Paint Protection Film, and cause unnecessary damage. TEVO Shiro increases the surface hardness and whilst retains the required flexible properties for Paint Protection Film, Vinyl Decal, car wrap, and matte paint finishing.

Ultraviolet Resistant Barrier

Oxidation on Paint Protection Film is a known phenomenon, often caused by the sunlight ultraviolet, and commonly happens after 1 to 2 years the material is installed on the car body. The brand new Shiro comes with Ultraviolet Resistant Barrier technology to slow down or minimize the oxidation process on Paint Protection Film. The barrier absorbs the highly energetic UV light, re-emits it at a lower energy state thereby dissipating the energy in a less dangerous form, and directly prolong the lifespan of Paint Protection Film. A strict condition must be met to activate the barrier – thickness of coating; 3 layers of Shiro are recommended for the barrier to be effective.

Ultra Watermark Resistant

Watermark problem has long existed since Paint Protection Film was invented and it is persisting to date although new Paint Protection Film does have hydrophobicity, nonetheless, the effectiveness does not last long. Shiro alters the characteristic of the surface, increase the water angle, and prolong the hydrophobic properties; as such, the watermark rate can be reduced to a minimal level. Not to mention that the new formula is enhanced with a new additive and the water contact angle is considerably improved from the standard ceramic coating.